Newsletter Subscribe

Enter your email address below and subscribe to our newsletter

Enter your email address below and subscribe to our newsletter

If you’ve ever owned, driven, or even just admired the legendary Audi 5 cylinder 10V turbo engine, you already know it’s a masterpiece of engineering. Known for its unmistakable sound, durability, and smooth power delivery, this engine has earned a cult following among enthusiasts.

But here’s the thing most people don’t talk about: one tiny, often-overlooked component plays a massive role in keeping this engine running strong—valve shims.

Think of valve shims as the unsung heroes of your Audi’s heart. They don’t make headlines like turbos or intercoolers, but without them, you’d be dealing with rough idles, power loss, or even serious engine damage.

In this guide, we’ll break down everything you need to know about valve shims on the Audi 5 cylinder 10V turbo—from what they are and why they matter, to how to spot problems, perform maintenance, and avoid costly mistakes.

Let’s dive in.

At first glance, valve shims don’t look like much—just tiny, precisely machined discs. But their job is critical.

In overhead cam engines like Audi’s 5-cylinder turbocharged 10V, valve shims sit between the camshaft lobes and the valve lifters (sometimes called tappets). Their role is to make sure there’s just the right amount of clearance between these moving parts.

That “clearance” is what allows your valves to open and close properly, which means:

Smooth airflow into the combustion chamber

Consistent fuel burning

Less wear and tear on the valvetrain

And of course, that silky-smooth Audi power delivery

Get the clearance wrong, and suddenly your engine is noisy, inefficient, and at risk of damage.

When it comes to performance and longevity, valve shims are far from optional. Here’s why they’re so important:

Engine Performance: Proper valve clearance ensures valves open and close at the right time, improving airflow and power.

Longevity: Without correct clearance, parts rub together or slam shut too hard, wearing out much faster.

Fuel Efficiency: Incorrect clearance = poor combustion = wasted fuel.

Noise Reduction: Ever heard that annoying tapping or clicking from an engine? Often, that’s bad valve clearance.

Bottom line? Regular valve shim checks and adjustments are the secret to keeping your Audi’s 5-cylinder running like new.

So how do you know if your valve shims need attention? Luckily, your Audi will give you some pretty clear hints. Look out for:

Tapping or Clicking Noises – A classic sign of excessive clearance.

Loss of Power – Valves not opening properly = weaker performance.

Rough Idle – The engine struggles to stay steady.

Increased Fuel Consumption – Bad combustion means more trips to the pump.

Engine Misfires – Valves not sealing correctly can cause cylinders to misfire.

If you’re experiencing one or more of these, it’s time to grab your tools—or your trusted mechanic.

For most Audi 5-cylinder 10V turbos, a good rule of thumb is to check valve clearance every 60,000 miles, or sooner if you notice the symptoms above.

This isn’t a “set it and forget it” kind of maintenance. Over time, wear and tear naturally throw valve clearance out of spec. Keeping an eye on it is crucial for both performance and engine health.

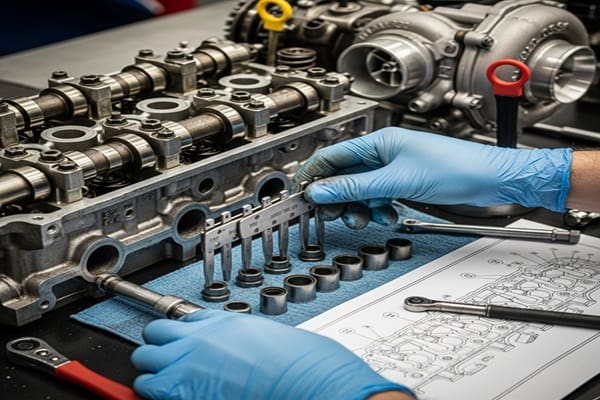

If you’re a DIYer, here’s what should be in your toolbox before tackling valve shims:

Feeler Gauges – To measure clearance accurately

Valve Shim Tool – To remove and install shims

Micrometer or Digital Caliper – To measure shim thickness

Replacement Shims – High-quality, correctly sized

Torque Wrench – To tighten everything back to spec

Now for the hands-on part. Here’s a simplified version of the process:

Start with a Cold Engine – Always adjust when the engine is completely cold.

Remove the Valve Cover – Carefully take it off to access the camshaft and lifters.

Measure Valve Clearance – Use your feeler gauge to check between the cam lobe and lifter.

Calculate the Correct Shim Size – If it’s out of spec, determine what shim thickness you need.

Swap Out the Old Shim – Use your shim tool to remove it.

Install the New Shim – Drop in the correctly sized replacement.

Double-Check – Always remeasure after installation to confirm it’s correct.

Reassemble – Torque everything back to spec, replace the valve cover, and you’re good to go.

Pro tip: Don’t rush this process. Precision is everything when it comes to valve clearance.

Also Read : How Sandboxing Helps in Identifying Malicious Software

Valve shims come in different thicknesses (usually in 0.05mm increments). To get the best results:

Always follow Audi’s clearance specifications.

Use OEM or high-quality aftermarket shims from trusted suppliers.

Avoid reusing old shims—they wear out and can throw off your measurements.

Even seasoned DIYers slip up sometimes. Here are some pitfalls to steer clear of:

Skipping Regular Inspections – Waiting until there’s a problem can lead to expensive repairs.

Guessing Shim Sizes – Always measure and calculate. Eyeballing it won’t cut it.

Not Rechecking After Installation – A tiny error can have big consequences.

Over-Tightening – Follow torque specs. Stripped bolts are no fun.

When you think about maintaining an iconic engine like the Audi 5-cylinder 10V turbo, valve shims might not be the first thing that comes to mind. But trust me—they’re one of the most important.

With regular inspections, proper adjustments, and the right tools, you’ll keep your Audi running smoothly, delivering that signature turbocharged growl for years to come.

So the next time you hear someone bragging about their turbo upgrade, intercooler, or exhaust, just smile—you know the real secret to longevity is in those tiny, mighty valve shims.

1. How often should I check and adjust valve shims?

About every 60,000 miles, or whenever you notice performance or noise issues.

2. What are the main symptoms of incorrect valve clearance?

Tapping noises, loss of power, rough idle, high fuel consumption, and misfires.

3. Can I reuse old valve shims?

It’s not recommended. Always replace them with new, properly sized shims.

4. What tools are required for adjustment?

Feeler gauges, shim tool, micrometer or caliper, replacement shims, and a torque wrench.

5. Does incorrect valve clearance affect fuel efficiency?

Yes—bad clearance leads to poor combustion and higher fuel consumption.